High Pressure Ship Airbags Upper Discharge Launching Air Bag

Marine airbag preparation before use

1. Clear and clean the sharp objects such as iron on the berth to avoid scratching the Marine airbag and causing unnecessary losses.

2. Place the Marine airbags at the bottom of the ship at a predetermined distance and inflate it. Obact the rising state of the ship and the pressure of the air bag at any time.

3. Upon inflating all Marine airbags, it is important to perform a thorough check on their state and ensure the ship is well balanced. Additionally, inspect the berth to ensure it is clean and tidy, promoting a safe and secure launch.

4. When utilizing airbags to launch a ship, it is crucial to begin with the stern first. This allows the stern to introduce the water surface, preventing any accidental scraping of the airbag by the propeller located at the back of the boat. Such precautions are necessary to ensure the safety of all personnel involved in the launch process.

Marine airbags performance

|

Diameter |

Layer |

Working pressure |

Working height |

Guaranteed bearing capacity per unit length(T/M) |

|

D=1.0m |

6-8 |

0.18MPa-0.22MPa |

0.5m-0.8m |

≥13.7 |

|

D=1.2m |

6-8 |

0.17MPa-0.2MPa |

0.6m-1.0m |

≥16.34 |

|

D=1.5m |

6-8 |

0.16Mpa-0.18MPa |

0.7m-1.2m |

≥18 |

|

D=1.8m |

6-10 |

0.15MPa-0.18MPa |

0.7m-1.5m |

≥20 |

|

D=2.0m |

8-12 |

0.17MPa-0.2MPa |

0.9m-1.7m |

≥21.6 |

|

D=2.5m |

8-12 |

0.16MPa-0.19MPa |

1.0m-2.0m |

≥23 |

Dimensions and specifications of Marine airbags

|

Size |

Diameter |

1.0m,1.2m,1.5m,1.8m,2.0m,2.5m,2.8m,3.0m |

|

Effective Length |

8m, 10m,12m,15m,16m, 18m,20m,22m,24m,Etc. |

|

|

Layer |

4layer,5layer,6layer,8layer,10layer,12layer |

|

|

Remark: |

According to different launching requirements, different ship types and different ship weights, the slope ratio of berth is different, and the size of Marine airbag is different. If there are special requirements, can be customized. |

|

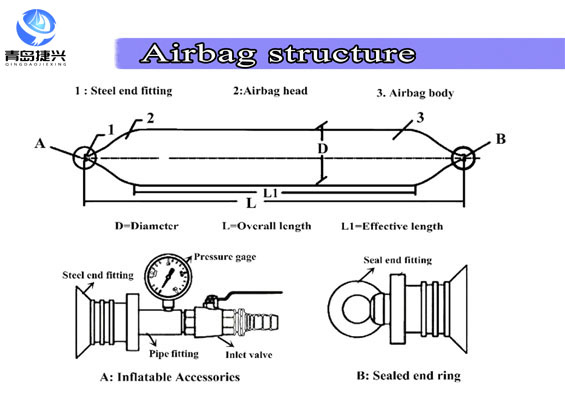

Schematic diagram of Marine airbag structure

Marine airbag fittings

Marine airbag case display